Our System

Enabling advanced guidance and automation.

Our mining guidance technology was first field-proven in the mid 1990s and has since undergone major developments to continually deliver significant results in a variety of mining applications.

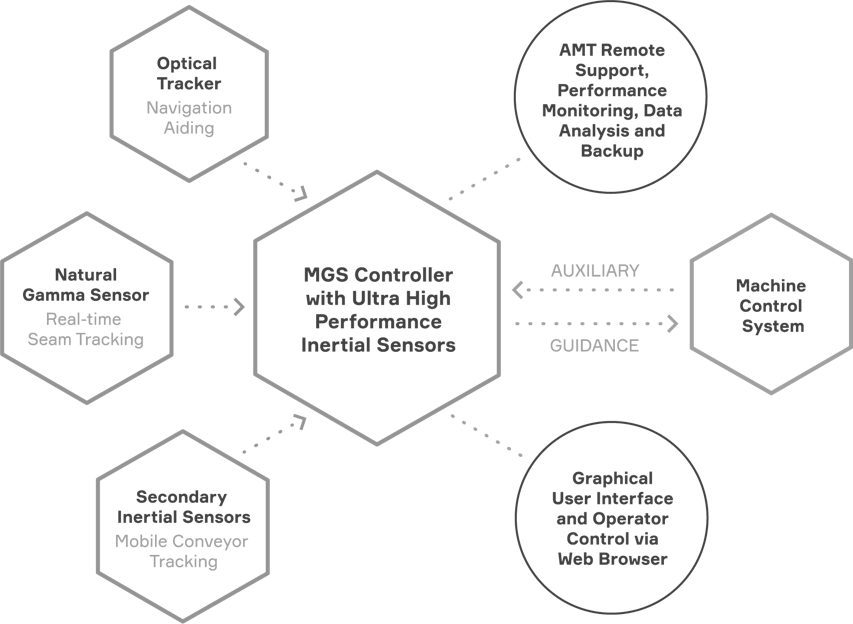

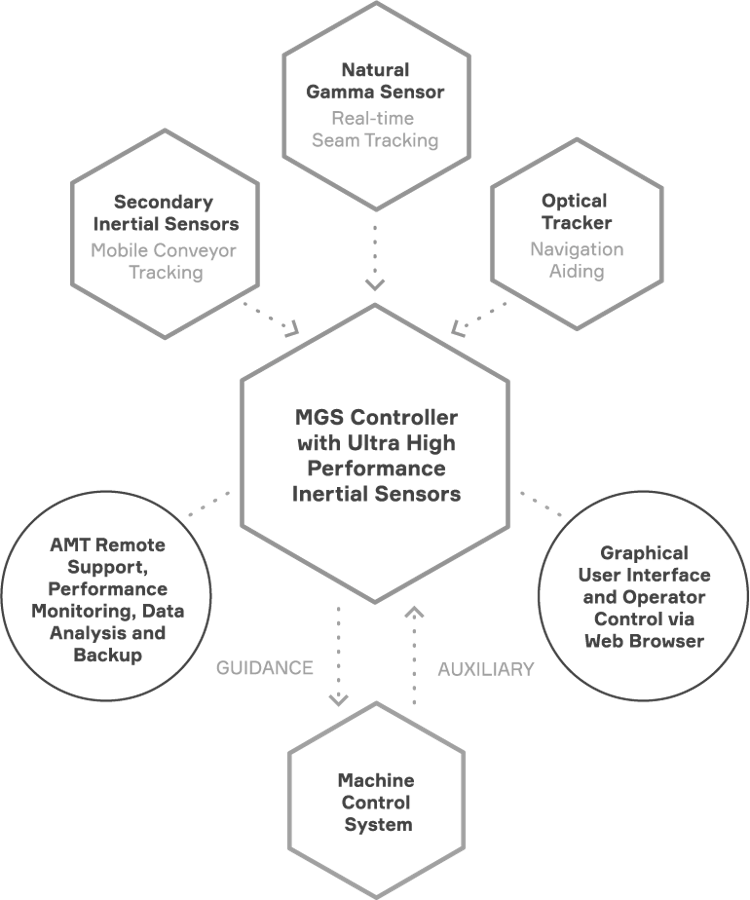

MINING GUIDANCE SYSTEM

The heart of our guidance technology

Our Mining Guidance System (MGS) incorporates high-performance military-grade inertial sensors and on-board data processing to compute the 3D position and attitude of the mining machine in local and global coordinates.

The system allows for high levels of mining machine guidance, control and automation, whilst increasing accuracy and safety, leading to significantly higher yields.

The Mining Guidance System incorporates the following features and functionality:

- A centralised system-level solution with tailored firmware to suit specific mining applications

- Designed for harsh mining environments, utilising advanced electronics and an integrated high performance processor

- Centralised system processing incorporating the core navigation solution and data processing algorithms for navigation and other automation components

- External control and automation information is made available via an industry standard, PLC-compatible Ethernet/IP data interface

- Designed for harsh mining environments including an IP67 rating

System Components

Process Aware Guidance

The AMT core mining navigation platform is customised for

each specific mining process and further developed in consultation with each

customer to meet the functional requirements of their mining operation. The multi-level

access controlled web interface can be customised for each customer’s operational

requirements. The incorporation of AMT seam tracking sensors allows the navigation

system to intelligently guide the mining process on-track and in-seam.

Machine Control and Automation

In additional to the fully featured web interface, an industry standard Ethernet/IP interface provides an auto-configuring interconnection with Ethernet/IP compliant machine PLC’s and controllers. A comprehensive set of high-rate control-critical MGS data is available via this interface as part of a tightly integrated machine control system.

If mobile conveyor/haulage systems are used as part of an

integrated mining system, the MGS can combine information from additional

distributed sensors to guide the path of the conveyor train.

Data Gathering and Analysis

The MGS provides an accurate track of the 3D position and pose of the mining machine during the entire mining process. Based on this, the MGS can accept user-defined external data for geo-referenced logging and post-analysis. The full navigation and geo-referenced data set is then available for analysis and visualisation as a complete set with the ability to drill down to single point location data.

All navigation and auxiliary data as well as unit

configuration and system status information can be synchronised to the AMT

secure cloud servers for backup, analysis and whole-of-mine visualization.

Remote Support

Each field deployed MGS unit is capable of self-detected firmware upgrades and auto-reporting of system health and performance information which is synchronised to the AMT secure cloud servers. AMT systems monitor and process this information to identify any early signs of hardware or performance issues and to provide routine summary performance reports to our customers.

AMT engineers can undertake most MGS diagnostic tasks via a customer-approved remote network access connection to each MGS installation. This also provides an effective means to apply configuration adjustments and fixes.